Visiting courses all over the country, we observe two common mistakes installing drainage that can actually cause your drainage problem to worsen as opposed to improve. The first is installing perforated pipe and gravel to an area where there is no control over the relief. This could be a lake or a river that fluctuates during rain events, or a tidal area that inundates the system on high tide.

In either case, a perforated pipe and gravel system immediately starts to function as a leach field instead of a drainage system. In a situation such as this, as the water level at the relief rises and fills the pipe with water, the water seeps out into the gravel bed and …

The Roaring Fork Club, a private golf and fly fishing club, is located just down valley from Aspen in one of the most beautiful natural settings in America. It is home to a Jack Nicklaus Signature course that plays along the Roaring Fork River.

As you can imagine, the winter snowfalls can be a real challenge for long time superintendent Matt Brewer to deal with in the spring. Matt turned to Turf Drainage Co. of America to help him with his most difficult areas. A strategic plan was done in 2010 to give the club a realistic appraisal of the overall cost of the project.

Next, the club decided which holes were the worst, and embarked on the first …

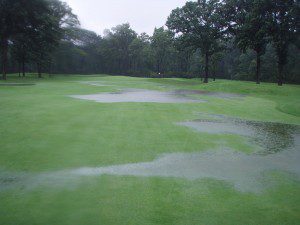

Franklin Hills Country Club and the term immaculate condition are synonymous. But, for Brian Schweihofer,the one aspect of the course that he was not pleased with was drainage.

Prolonged wet stretches, such as what the Midwest expereienced in 2011, meant missing mowing opportunities that kept Brian from having the course in tournament condition every day. Brian and Dennis Hurley, President of TDA, spent three days walking the course in order to provide the club with a detailed plan of what was needed to gain control over the course during wet periods. The membership approved the plan by a wide margin in July, and will start the first phase of construction in September of this year.

Siphon Systems, Inc, a certified …

The principle of Concentrations of Flow appears in many aspects of drainage. Understanding that it is critical to proper drainage design. It simply states that as water moves from larger areas through smaller areas, flow rates increase.

We see this every day on our golf courses when water runs off of hillsides. Not only is the bottom of the slope the wettest, but areas that run between mounds or valleys where the flow travels will be the wettest. These areas have to handle not only the water that is falling on the flow area, but the water that has fallen on the watershed above it. If we don’t collect this water before it concentrates in these areas, the heavy Concentrations …

We see this every day on our golf courses when water runs off of hillsides. Not only is the bottom of the slope the wettest, but areas that run between mounds or valleys where the flow travels will be the wettest. These areas have to handle not only the water that is falling on the flow area, but the water that has fallen on the watershed above it. If we don’t collect this water before it concentrates in these areas, the heavy Concentrations …

A master drainage plan can give you, the superintendent, a way to clearly present the status of your drainage problem to your committee or owner. Pat O’Brien wrote an article in the September, 2005 issue of the USGA Greens Section Record regarding the importance of starting a drainage project with a plan.

Trey Cutshall, Superintendent at The Farm Golf Club, says “Until we did the drainage plan with TDA, we didn’t have a real grasp on the scope of the project. By being involved during the planning process, I knew that the areas that I felt were important were being included, and I had a much better understanding of what the options were in each area. Once we did …

Trey Cutshall, Superintendent at The Farm Golf Club, says “Until we did the drainage plan with TDA, we didn’t have a real grasp on the scope of the project. By being involved during the planning process, I knew that the areas that I felt were important were being included, and I had a much better understanding of what the options were in each area. Once we did …

Not a month goes by at TDA that we don’t talk with a golf course that has incurred major damage to their existing drainage system as the result of having had an irrigation system installed with a vibratory plow. The reasoning is always the same. “The cost difference to trench it in wasn’t worth it. Besides, the contractor told me that they do it all of the time and it isn’t a problem.”

Cutting a drainage line while installing an irrigation system isn’t like cutting an irrigation line when you install drainage. You may not know a drainage line has been cut for several seasons. Even rains right after the irrigation project is completed might not tell you all of …

The most common technical question we are asked “Doesn’t the fabric around the drain clog up?”

The most common technical question we are asked “Doesn’t the fabric around the drain clog up?”

The answer takes more than a simple “no” or “yes.”

Most of the misunderstanding about geotextiles comes from their original introduction into the golf course industry when they were first used as “socked pipe.” The industry installed the “socked pipe” into a bed of gravel. When failed systems were removed from the ground it was noticed that clay and silts had accumulated around the sock and the sock was blamed for the drainage failure.

In reality, the gravel had failed because it was not sized properly for the native soils. If the gravel had been the proper backfill the fines would have never reached …

We at Turf Drainage Co. of America have always advised against the use of gravel in fairway drainage installations. The correct solution is to use a properly sized sand as the backfill material. Let the designers at TDA show you how you can build a technically correct system at your course.

We at Turf Drainage Co. of America have always advised against the use of gravel in fairway drainage installations. The correct solution is to use a properly sized sand as the backfill material. Let the designers at TDA show you how you can build a technically correct system at your course.

With conventional drainage, the pipe needs to be installed with enough grade that the water flowing through the pipe will have enough velocity that contaminants won’t clog the system over time, thus the term “self cleaning velocity.” Self Cleaning Velocity in drainage manuals is stated as a minimum flow of 3 feet per second. At this flow rate, a pipe will be flushed of contaminants and remain open.

The slope needed for a pipe to maintain this velocity is based on the Manning number of the pipe. This number calculates the friction as the result of wall construction and diameter. It is generally accepted that smoothwall 4″ pipe placed at a 1% slope will provide adequate velocity in a system …

We see this every day on our golf courses when water runs off of hillsides. Not only is the bottom of the slope the wettest, but areas that run between mounds or valleys where the flow travels will be the wettest. These areas have to handle not only the water that is falling on the flow area, but the water that has fallen on the watershed above it. If we don’t collect this water before it concentrates in these areas, the heavy Concentrations …

We see this every day on our golf courses when water runs off of hillsides. Not only is the bottom of the slope the wettest, but areas that run between mounds or valleys where the flow travels will be the wettest. These areas have to handle not only the water that is falling on the flow area, but the water that has fallen on the watershed above it. If we don’t collect this water before it concentrates in these areas, the heavy Concentrations … Trey Cutshall, Superintendent at The Farm Golf Club, says “Until we did the drainage plan with TDA, we didn’t have a real grasp on the scope of the project. By being involved during the planning process, I knew that the areas that I felt were important were being included, and I had a much better understanding of what the options were in each area. Once we did

Trey Cutshall, Superintendent at The Farm Golf Club, says “Until we did the drainage plan with TDA, we didn’t have a real grasp on the scope of the project. By being involved during the planning process, I knew that the areas that I felt were important were being included, and I had a much better understanding of what the options were in each area. Once we did